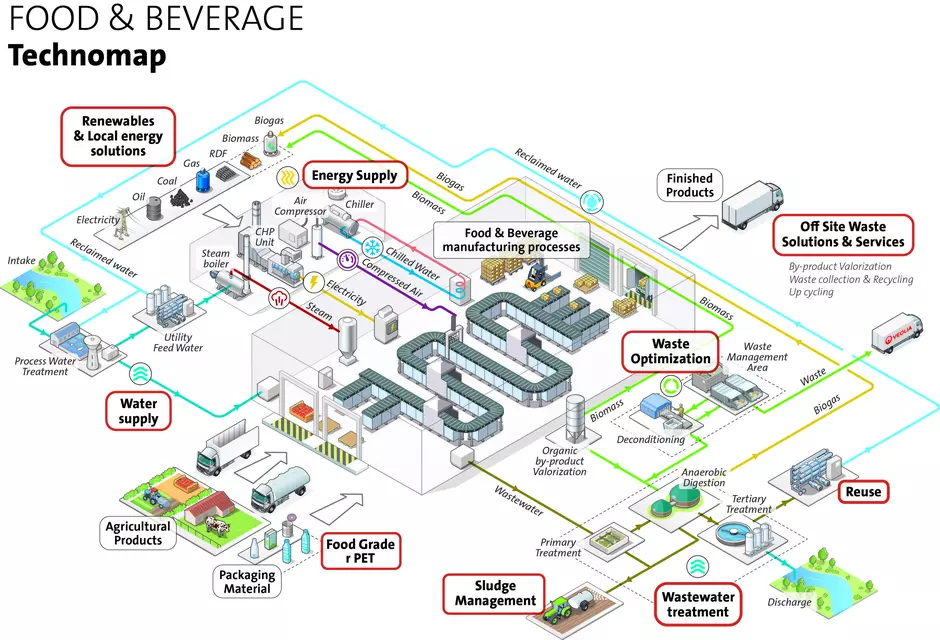

Veolia Water Technologies offers the food and beverage industry a large panel of solutions to produce the safest ingredient water and high-quality utility water. From standard equipment to engineered solutions, services, maintenance and complete water cycle management, we will help you optimize the quality of your purified water and eliminate contamination.

High-quality standards: challenges faced by food and beverage companies

The quality of the water has a direct impact on the product’s taste, safety and longevity.

Water supply issues related to seasonality and legal pressures.

Ingredient water requirements have to fulfill the highest international standards.

How Veolia is committed to helping the food and beverage sector

Our engineers and process specialists along with field-based service teams can manage all stages of water purification and contaminant removal.

As water cycle experts, we also help you meet regulatory and environmental compliance through treating wastewater streams and reducing water consumption while identifying solutions that also deliver value through compliance, for example by generating renewable energy from biogas or reducing greenhouse gas emissions.

We manage health risks through the use of our preventative water treatment solutions and programs. Our wide experience includes securing and sanitizing ingredient water as well as water used in cooling towers. Our ingredient water quality guarantees protection against legionella.

We can improve production processes from the inside out to support sustainable development. Our global expertise enables us to further support customers in the standardization of equipment, recycling of treated effluents, and the adoption of alternative supply sources.

We help our partners manage their wastewater to limit water use and reduce their carbon footprint.

Our solutions help optimize energy and chemical consumption.

Adaptable solutions for all food and beverage players

Water is found in all components of the production chain: from raw materials to cooling systems, as well as sanitary installations.

Ingredient water (production)

Production facilities need a continuous and safe supply of water. Veolia’s technologies ensure that the production of ingredient water is reliable, cost-effective and meets the highest quality standards that your operation demands.

Utility water

Food and beverage manufacturers rely upon their utility operations to provide reliable steam and cooling water to support production needs. Veolia Water Technologies’ equipment and chemical technologies effectively produce the type of water your utilities need to ensure steam quality, heat exchange efficiency and environmental compliance.

Wastewater

Veolia Water Technologies is experienced in helping clients reduce their financial exposure and comply with wastewater discharge requirements and stringent environmental regulations.

Water recycling and reuse

Food production is a water-intensive industry. Veolia Water Technologies understands this and is able to help clients meet water reduction goals and minimize their environmental impact by implementing technologies that convert wastewater into water that can be reused elsewhere.

Although not the most water-intensive industry, it is one of the biggest of its first users and water quality is a crucial issue for the food and beverage sector – water purity must be at the right level so as not to alter the characteristics of the food and beverage products.

Convert waste and wastewater to energy

Anaerobic treatment technologies offer a dual benefit for food and beverage facilities. They simultaneously treat a wide range of waste and wastewater streams while creating energy-rich biogas as a by-product that can be used to produce “green” electricity or heat.

Nutrient recovery

Veolia Water Technologies’ sustainable approach to water can transform waste into valuable by-products, such as fertilizer, that can be reused or sold.

Product filtration

Our fine filtration technologies ensure product quality and clarity. These systems are a safe and economical method to remove suspended solids and other unwanted particles from your product.

Strong partnerships with food and beverage companies worldwide

Veolia Water Technologies has more than 1,000 reference projects in the food and beverage industry. Our 7,700 employees worldwide provide the group with solid expertise in key industry areas.

We are recognized for our expertise in the food and beverage sector. We use this expertise to support the aquaculture and dairy industries, as well as meat processing, fruits and vegetables. We also enable the manufacture of oil in optimal conditions.

Also present in the beverage sector, we work closely with breweries, soft drink producers, spirit producers, and distilleries. Finally, we offer guidance from the initial concept to plant operation for alternative proteins manufacturers.

A world-first technology created in the water-stressed state of Jalisco.

Nestlé has taken to achieve its 2030 ambition to have zero environmental impact from its operations and as part of this we were tasked to conserve scarce groundwater resources and limit water extraction.

Working alongside dairy technology firm GEA Filtration, our Mexican team added new Cero Agua (zero water) technologies to the already constructed plant.

Discover our water treatment technologies for the food and beverage industry

Our technical and environmental services use advanced water technologies, guaranteeing compliance with continuously strict health standards for our food and beverage customers. Our solutions ensure optimum ingredient water quality and meet stringent requirements for disinfection and purification.

Technologies - Food and beverage

There are significant reputational and financial consequences to putting people, products or the environment at risk through poorly managed systems and processes. Selecting equipment that is reliable, effective and easy to operate and maintain is therefore especially important to the food & beverage industry. For many food processors, sustainability is equally important and they are working towards the reuse of water for landscaping, equipment washing, cooling towers, boilers, evaporators, chillers, dust control and irrigation systems. Veolia Water Technologies provides the technologies and expert know-how to help them ensure their processes operate in a safe, reliable and sustainable way.

Peter Stokes

Director — Global Accounts

Veolia Water Technologies

Contact Peter through his LinkedIn account

Would you like more information about our technologies for the Food and Beverage industry?

Resources

To learn more about water treatment systems for food and beverage manufacturers, download our Pocket Guide to Ingredient Waters.

More services for our food and beverage clients

FAQ about water solutions for food and beverage companies

How is water used in the food and beverage industry chain?

Process water

Process water is used for equipment and installation cleaning, washing of raw materials, the transportation of products, flushing and much more. The water is typically potable water grade, a requirement for product contact applications.

Our technologies: Ionsoft, Sirion, Rapide Strata

Ingredient water

Ingredient water is a higher-grade process water. It is typically used in the fabrication of soft drinks, bottled waters and infant nutrition products. Potable water is treated using hygienically designed equipment to manage microbial contamination risks while minimizing the use of chemicals that could compromise the end product.

Our technologies: Nurion, PurBev / HyBev, Sirion

Utility water

Food and beverage manufacturers rely on their utility operations to provide reliable steam and cooling water to support production needs.

Our technologies: Ionsoft, Sirion, Rapide Strata

Wastewater and sludge

Food and beverage manufacturing results in wastewaters with high levels of biochemical oxygen demand (BOD), chemical oxygen demand (COD) and nutrients due to the presence of leftover organic materials. Treatment is often required to ensure discharge compliance and avoid costly penalties. Variability in production runs can make treatment more complicated. Within this application, we offer anaerobic treatment and nutrient recovery.

Our technologies: Idraflot, Biothane, AnoxKaldnes

Water recycling and reuse

Food production is a water-intensive industry. Short-loop recycling is used within processes to optimize in-process water usage and reduce the load on the wastewater plant. Wastewater can be appropriately treated and recycled back to non-food contact applications.

Can wastewater be treated and made safe for use in food and beverage products?

There is no technical reason why wastewater cannot be treated to a high level of purity to allow its reuse in the food & beverage industry. However, it is important to identify the food safety hazards related to each water use. For example, reusing water in a cooling tower system for a refrigeration plant carries almost no food safety risk whilst using treated wastewater as an ingredient carries a higher risk.

It is useful to start by categorizing water uses in the factory according to risk of product or food contact. Some countries have legislation as to the reuse of wastewater and many companies also have their own internal standards of where wastewater can be reused.

How much water is used in the food industry?

Food and beverage production is reliant on water, with an estimated 70% of all extracted freshwater consumed by the industry being directly used in agriculture to grow the crops, etc. Different types of products and manufacturing processes require varying quantities of water, typically in the range of 2 to 20 litres of water per 1 kilogram of product. The majority of companies operating in this sector now benchmark their water consumption as a key metric to their operating performance and are taking steps to ensure they operate within the industry best practice by implementing water reduction, recycle and reuse technologies.